Having assisted as much as I felt I could on ‘London Road’, I turned my attention and time to the Christmas at the Conservatoire, and the role which would form the majority of my assessment in this allocation. Unlike a normal production process, this show is always jammed on at the end of the year leaving very little time for prep and planning. As such, my lack of prior involvement was not a massive hurdle in my ability to find things to do, taking the initiative to draw up plans and a basic rig design, taking inspiration from my experience on the same show last year. With Reece incapacitated by his work on London Road, I took the lead in preparation of the show and after Grant had decided what he wanted in the air – and that we should endeavour to work from stock as much as possible – I set about drafting up a Vectorworks plan for TSM and LX to use. This tested my basic knowledge of Vectorworks and forced me to learn more detailed aspects of the programme – from using pre-drawn components like deck and drapes, to rendering three dimensionally within a pre-existing venue plan. That venue plan proved to be an issue for the project, however. As part of a negotiated project for the previous year, a now graduated student had drawn the Stevenson Hall in great detail, and we made the decision to use this detailed plan over the basic PDF one already in existence. We reasoned that, for a show like Christmas at the Conservatoire, beam and bar positions would be integral, as these would be where we ended up rigging pulley points for our blacks, and motor points for our truss. However, upon Steve pointing out a minor discrepancy in the back wall dimension, and through the venue reccie which followed, it became clear that the plan was quite inaccurate. The upstage line of acoustic panelling was shown to be 1.5m into the space when it actually lay against the back wall, the orchestra risers were rendered around a third of their actual size, and the width of the room itself was about a meter out. This was infuriating – not least because of the fact we had already marked out the rehearsal room for the cast and Director. However, upon reflection, I am glad that we found the mistakes when we did, as had we gone any further with the planning process or into the rig with the inaccuracies still present, it would have slowed us down considerably, or forced us to rethink our entire rig plan. In future, I will make sure to check the accuracy of any pre-existing plan before I use it.

Malki Dead Hangs the US Black in a Harness

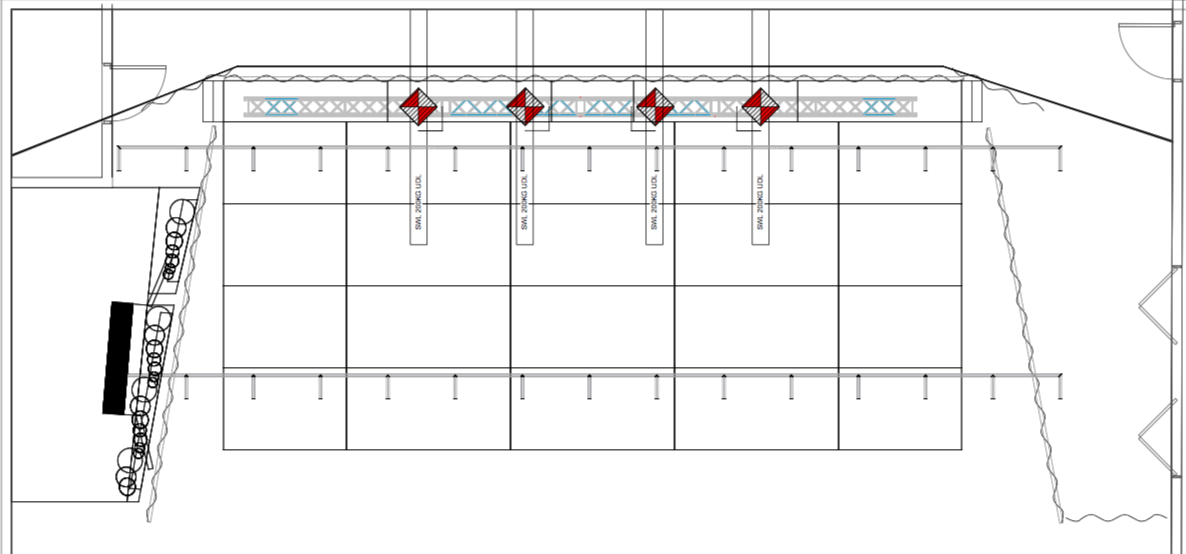

With venue planned and rig finalised, Reece and I spent a slow prep-week cutting legs for deck, pulling masking and drifts, and ensuring that we had everything looked out and marked up in a way so as to quicken the fit-up on the Sunday. Remarkably – this worked. Once we got started the fit up went relatively smoothly. I took our crew to transport all the equipment from the dock to the venue with Reece staying behind to help swing the front of house motors to the upstage beams in preparation for the new truss. Once this was complete, my team progressed to rigging the upstage and side stage blacks, the former of which was dead hung by Malki onto 1.5m drifts. This gave us a trim height that we could level all masking to, ensuring we didn’t have to eyeball the back black straight. Once we had tied on the side blacks we realised that our pole was around a meter shorter than we thought – mainly because the venue differed from the plan’s sizing. To rectify this, we added a 1m scaff section and coupler to the upstage end, attaching a new barrel clamp to this extension. From the catwalks, Malki then described the knots he wanted me to tie – running the line through the shackle on one clamp, up to an alpine butterfly, and then down to a bowline on the other clamp. This created a bridle in the line which meant we didn’t have to run another down, or lift the upstage side of the bar just from the extension bar. After the blacks had been hung, we flew the back truss which we had hung on the four venue 1/4T motors. And whilst LX rigged their lamps, we fitted braces to the 1.4 x 6m hard masker that would form the DS side of the SL wing, so as no audience could accidentally enter the backstage are. It was at this point that we realised that we could still see some of the red tabs upstage, as the cast entrances were wider than initially thought. Reece suggested using two extra hard maskers, which were promptly brought into the venue and erected – solving the issue quickly. It was this ability to look at a problem, settle on an solution, and set to fixing it that I feel Reece and I achieved quite well, and I certainly respected him for his ability to deal with any issues without making a big deal of their existence. We just got the job done.

‘Tying on the Y’ to Support the Extensions

The risers slid downstage with a lot of pushing and the deck was slotted in behind it, bolted together for stability, and the kickrail screwed in. Due to the nature of the Stevenson Hall and our inability to screw into the floor, we ratchet strapped both sets of treads to the legs of the deck on either side. This ended up being a great test of my communication skills, as the crew member who had volunteered to be under the deck and tighten the strap didn’t actually know how to use a ratchet. I explained to them how the straps worked and how I wanted it done, and they were able to carry out the task.

SaveSave