As a result of my allocation reshuffle in mid-October, it was agreed that I would Swing Stage Tech between the Studio and Main House show during their fit up periods, before moving on to prep for Christmas at the Conservatoire when those shows moved into tech. Following a rather curt conversation with the TSM of the Ath, however, it became clear that all of this additional time would be spent in the Chandler on ‘London Road’.

As this is not usually a job which exists in the allocations process, I found my role was able to develop into whatever it needed to be on any specific day, in order to deal with the needs of any department who required some extra help or who weren’t progressing as quickly as the others. This was incredibly rewarding, as – like Die Fledermaus last year – I got to spend time helping many different departments and using many different sets of skills in a way that was helpful, not just to my learning, but to the advancement of the production.

Predominantly, I spent my time with the Stage Department, assisting Reece, Dylan, Alan, and crew during their fit up. Having worked in the Chandler excessively last year I knew the quirks of the venue really well, and this came in useful when issues like rigging bars onto the I beams behind the pillars presented themselves. Here, I suggested using ring bolts to flange clamps as we had done on the CPP shows, as these would tighten onto the beam and leave a fixing point big enough for a 1T shackle to fit through, which could then lead on to a clamp and the bar. Once these LX ladders were in position we could focus on the tree, which arrived into the venue attached to dollys, with a center section already hollowed out. Raising the tree onto the post proved to be a much harder task than it first appeared, however, as every point we could see to strop around or attach to would also prevent us slipping it around the structural pole as we required it to be. Eventually, flying irons were attached to the front of the trunk with coach screws, and a chain block used to lift the front of the tree until it could be swung back and sheath the pole. Once this was in position, these fixings could be removed, a ratchet strap attached around the top for stability, and a tension line comprised of a drift, turnbuckle, and stitch sling attached to the bottom, as further resistance to any possible toppling.

The Tree Rises

The next technical element to be rigged was the kabuki sniffer. Though originally intended to just sniff into a PVC tube, it was commented that the small opening and the sharp edge posed the danger that the material would rip – something which could not be allowed to happen. The suggestion was then given that we attach a cone to the front of the tube. Steve and I went scavenging in the dock to see what we could construct this out of, eventually settling on cutting the top and tail off a traffic cone, and securing this to the tube with gaffer tape. This worked surprisingly well and, after being blacked over, collected the cloth without any snags. The next issue was how to make the line retract into the sniffer when tension from the kabuki was released. The original idea was to have weights on the other end of the line which would drop, pulling the material up – however, in practice, this didn’t travel a far enough distance to collect all of the material in with enough speed. In unison, Steve and I suggested making it double purchased, and this looked like it had a greater chance of working. However, on further testing, this still didn’t provide enough travel, and the solution was dropped in favour of a crew member running with the line down the upstairs corridor, collecting the material in the sniffer as they went. This was another example of the importance of planning a backup for risky ideas, as the odds of the first concept succeeding are quite small in comparison to its chances of failure.

As London Road progressed into the tech period, I was in the venue less and less, attending when called by Reece as a spare pair of hands for some of the more technically demanding or challenging fix jobs where he didn’t want to call his entire first-year crew. Through these small tasks, I found ways of deploying my knowledge of things like knot and rope work, along with bridle building, and it also gave me more opportunities to actively think up solutions on the spot, and then go and rig them as I devised. Overall, I’d say my experience assisting with London Road was a positive one, as it gave me a chance to work with a new set of people on a new project and further develop on some existing skills. Working with the first years let me develop my communication through teaching knots or explaining how I’d suggest they go about completing a task, and working with Reece has challenged my problem-solving abilities and my ability to devise multiple solutions to combat any one issue.

SaveSave

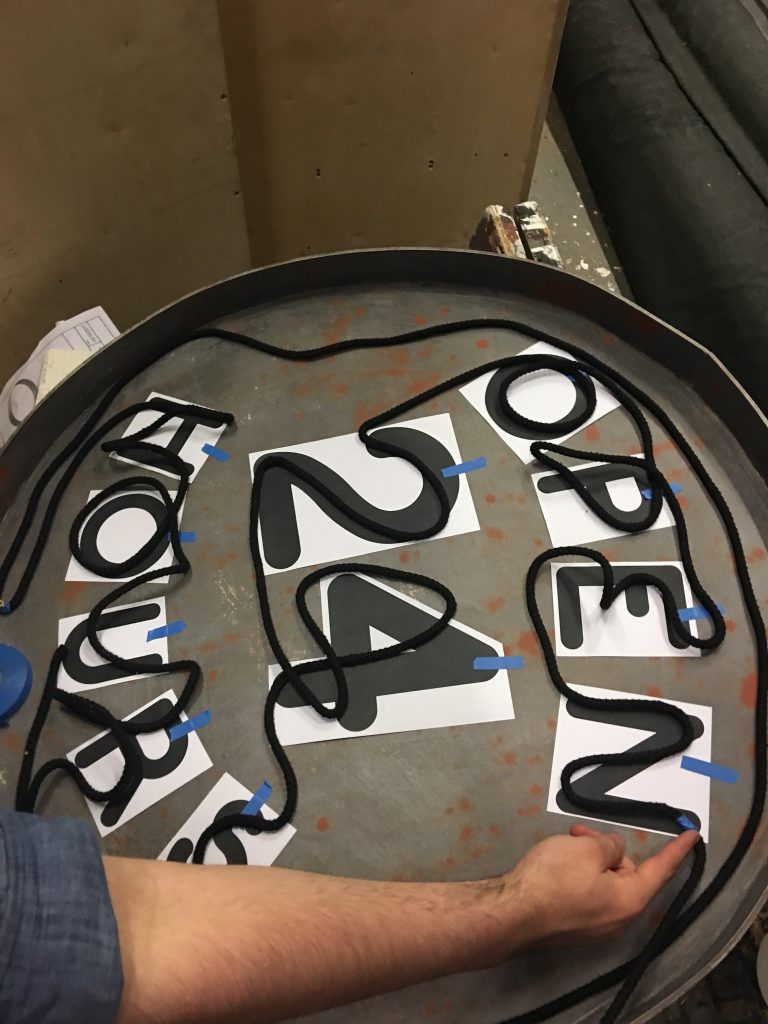

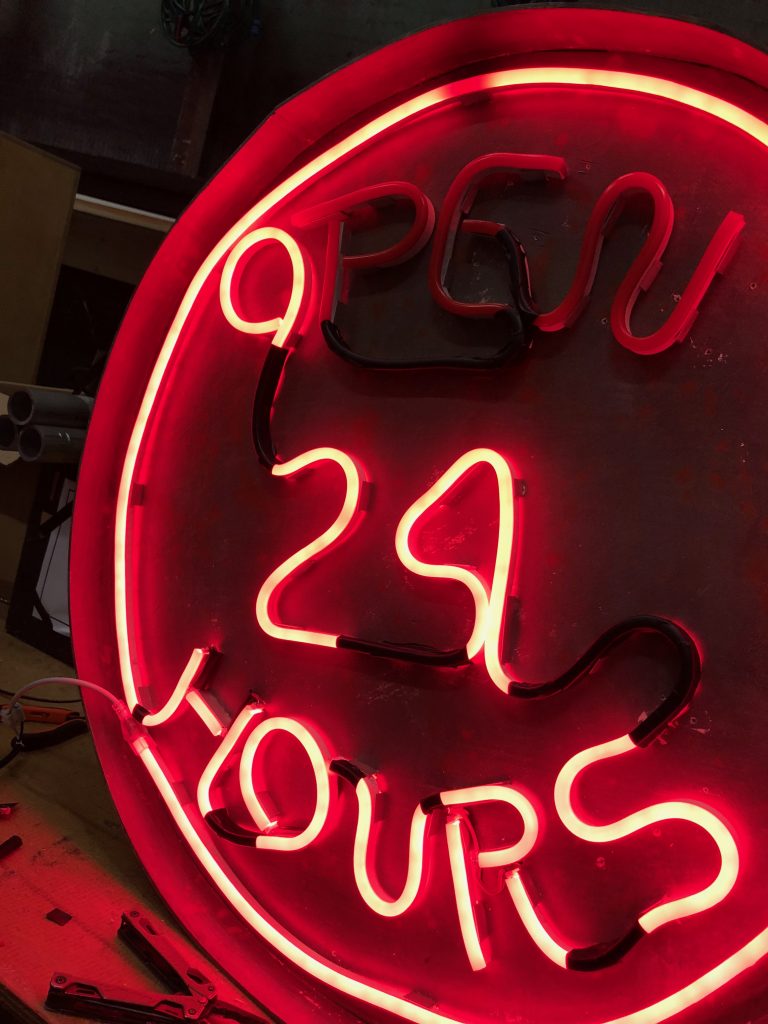

After Jazz had demonstrated how we needed to cut and solder the tubing, Karyn and I were left to complete the project. This was one of the first instances that showed that, despite best efforts, I am not a natural fine worker. Due to a combination of naturally shaky hands, and tools not being designed for left handed users, I melted through one of the connectors when trying to solder it, resulting in some angry cutting and expletives to try and make it work. I tried again, another two times, with better results, before succumbing to the conclusion that I should stick to hacksawing the metal mounting plates and leave Karyn to solder the remainder of the sign. This was mildly disappointing, as its definitely a skill I’d have liked to improve on and master to however far I could – though I realise that it wasn’t the kind of situation where mistakes could be easily rectified and that there’d be times in future when I could develop on this further without the production pressure of definitely having to get it right first time. So, after about three days of blood (hacksaws are painful on your fingers), sweat, and almost tears, our sign was working and ready to be installed. I don’t think it would be an exaggeration to say that I’ve never been happier with something I’ve had a part in making for a show, and I was genuinely very proud of what Karyn and I had achieved. After prepping the rest of our kit, screwing together some pendants, and still riding a neon high, we went into fit-up.

After Jazz had demonstrated how we needed to cut and solder the tubing, Karyn and I were left to complete the project. This was one of the first instances that showed that, despite best efforts, I am not a natural fine worker. Due to a combination of naturally shaky hands, and tools not being designed for left handed users, I melted through one of the connectors when trying to solder it, resulting in some angry cutting and expletives to try and make it work. I tried again, another two times, with better results, before succumbing to the conclusion that I should stick to hacksawing the metal mounting plates and leave Karyn to solder the remainder of the sign. This was mildly disappointing, as its definitely a skill I’d have liked to improve on and master to however far I could – though I realise that it wasn’t the kind of situation where mistakes could be easily rectified and that there’d be times in future when I could develop on this further without the production pressure of definitely having to get it right first time. So, after about three days of blood (hacksaws are painful on your fingers), sweat, and almost tears, our sign was working and ready to be installed. I don’t think it would be an exaggeration to say that I’ve never been happier with something I’ve had a part in making for a show, and I was genuinely very proud of what Karyn and I had achieved. After prepping the rest of our kit, screwing together some pendants, and still riding a neon high, we went into fit-up.